Rexroth Hydraulic Pump Parts A10VSO Series Displacement 16~180

Our factory has multiple brands REXROTH,HITACHI,SAUER DANFOSS etc.. hydraulic pump parts, pump, motor of good quality and reasonable price in stock, which can be delivered to customers in the first time .contact us to confirm more details !

Application

Rexroth A10VSO series Widely used in a variety of engineering machinery, plastic machinery, metallurgical machinery, pressing machinery and other large machinery.

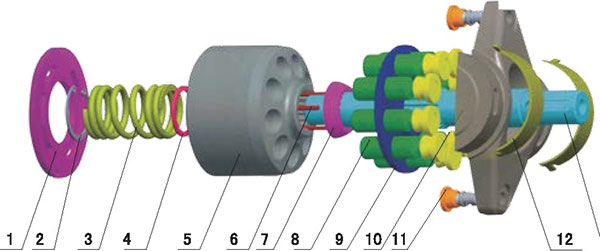

Product Information

|

ITEM |

DESCRIPTION |

QUANTITY |

ITEM |

DESCRIPTION |

QUANTITY |

|

1 |

VALVE PLATE L |

1 |

10 |

SWASH PLATE R |

1 |

|

VALVE PLATE R |

1 |

|

SWASH PLATE L |

2 |

|

|

VALVE PLATE M |

1 |

11 |

SADDLE BEARING |

2 |

|

|

2 |

SNAP RING |

1 |

12 |

DRIVE SHAFT |

1 |

|

3 |

COIL SPRING |

1 |

13 |

DFR CONTROL |

1 |

|

4 |

SPACER |

2 |

14 |

COUNTER PISTON |

1 |

|

5 |

CYLINDER BLOCK |

1 |

15 |

COUNTER PISTON GUIDE |

1 |

|

6 |

PRESS PIN |

3 |

16 |

PISTON |

1 |

|

7 |

BALL GUIDE |

1 |

17 |

PISTON |

1 |

|

8 |

PISTON SHOE |

9 |

|

|

|

|

9 |

RETAINER PLATE |

1 |

|

|

General Notes

The A10VSO pump is designed to be used in open circuit.

Project planning, installation and commissioning of the axial piston unit require the involvement of qualified personnel.

Before operating the axial piston unit, please read the appropriate instruction manual thoroughly and completely. If necessary, request these from Bosch Rexroth.

During and shortly after operation, there is a risk of burns on the axial piston unit and especially on the solenoids. Take appropriate safety measures (e.g. by wearing protective clothing).

Depending on the operating conditions of the axial piston unit (operating pressure, fluid temperature), the characteristics may shift.

Service line ports:

The ports and fastening threads are designed for the specified maximum pressure. The machine or system manufacturer must ensure that the connecting elements and lines correspond to the specified application conditions (pressure, flow, hydraulic fluid, temperature) with the necessary safety factors.

The service line ports and function ports are only designed to accommodate hydraulic lines.

Pressure cutoff and pressure control do not provide security against pressure overload. A separate pressure relief valve is to be provided in the hydraulic system.

The data and notes contained herein must be adhered to.

The product is not approved as a component for the safety concept of a general machine according to DIN EN ISO 13849.

The following tightening torques apply:

Fittings:

Observe the manufacturer‘s instruction regarding the tightening torques of the used fittings.

Mounting bolts: For mounting bolts with metric ISO thread according to DIN 13 or thread according to ASME B1.1, we recommend checking the tightening torque individually according to VDI 2230.

Female threads in axial piston unit:

The maximum permissible tightening torques MG max are maximum values for the female threads and must not be exceeded. For values, see the following table.

Threaded plugs:

For the metal threaded plugs supplied with the axial piston unit, the required tightening torques of the threaded plugs MV apply. For values, see the following table.

|

Ports Standard Thread size |

Maximum permissible tightening torque for female threads MG max |

Required tightening torque for threaded plugs MV |

Size of hexagon socket of threaded plugs |

|

|

DIN 3852 |

M14 x 1.5 |

80 Nm |

45 Nm |

6 mm |

|

|

M16 x 1.5 |

100 Nm |

50 Nm |

8 mm |

|

|

M18 x 1.5 |

140 Nm |

60 Nm |

8 mm |

|

|

M22 x 1.5 |

210 Nm |

80 Nm |

10 mm |

|

|

M27 x 2 |

330 Nm |

135 Nm |

12 mm |

|

DIN ISO 228 G 1/4 in |

70 Nm |

– |

– |

|

About Tansportation

Cooperation Partners

Contact us

Visen

Sales Manager

Company Introduction

Qingdao Runfeng Hydraulic Co., Ltd. has more than ten years of experience in hydraulic parts production and international trade. We use the highest quality raw materials for production and provide the highest quality accessories available worldwide. We are your trusted supplier of hydraulic components in China.

Here, you can not only get the best quality accessories, but also get the best service and long warranty period.

Exquisite transportation packaging, fast shipping service, and high-quality accessories make us the best choice for you.

Product Application

Engineering Plant

Hydraulic pumps and motors on equipment such as excavators, pavers, rollers, drills, bulldozers, heavy excavators, road mixers, etc.

Construction Machine

Hydraulic pumps, motors, etc. on concrete pump trucks, concrete pump truck transporters, concrete mixer trucks, pile drivers and other equipment.

Industrial Equipment

Hydraulic pumps and motors on polyurethane foam machines, ceramic presses, plastic machinery, chemical equipment, metallurgical equipment, etc.

Ship Aviation

Towing ship machine. Anchor cranes, cranes, dredgers, dredging vessels, etc. are used in ship control systems and hydraulic pumps and motors in operating systems.

About Package